vaillant ecotec pro 28 installation manual

Get your Vaillant EcoTec Pro 28 installation manual here! Easy download, expert guidance for seamless boiler setup.

The Vaillant EcoTEC Pro 28 is a high-efficiency, wall-mounted boiler designed for reliable heating and hot water supply. Its compact design and advanced technology ensure energy efficiency and optimal performance.

What is the Vaillant EcoTEC Pro 28?

The Vaillant EcoTEC Pro 28 is a high-efficiency, gas-fired, wall-mounted boiler designed for domestic heating and hot water systems. It combines advanced technology with a compact design, making it suitable for a wide range of properties. The boiler operates at high efficiency, reducing energy consumption and lowering utility bills. It features a built-in timer and is compatible with Vaillant’s intelligent eBUS system, allowing for seamless integration with smart controls. The EcoTEC Pro 28 is known for its reliability and durability, offering consistent performance for both central heating and hot water supply. Its wall-mounted design saves space, and the removable control panel simplifies servicing. With a focus on energy efficiency and user convenience, the Vaillant EcoTEC Pro 28 is a popular choice for modern heating systems.

Importance of the Installation Manual

The installation manual for the Vaillant EcoTEC Pro 28 is crucial for ensuring a safe, correct, and efficient setup of the boiler. It provides detailed instructions tailored to the unit’s specifications, helping installers comply with safety standards and manufacturer guidelines. Proper installation is essential for optimal performance, energy efficiency, and longevity of the boiler. The manual also outlines essential safety precautions to prevent hazards like gas leaks or electrical issues. Additionally, it guides installers through compliance with local regulations and warranty requirements. By following the manual, professionals can avoid common mistakes, ensuring the boiler operates efficiently and safely. Regular reference to the manual during installation and maintenance helps uphold the system’s reliability and performance over time.

System Requirements

The Vaillant EcoTEC Pro 28 requires specific conditions for optimal operation, including a stable gas supply, proper ventilation, and compatible electrical connections. It must be installed in accordance with local regulations and safety standards.

Gas Supply Requirements

The Vaillant EcoTEC Pro 28 requires a reliable gas supply to operate efficiently. It is compatible with natural gas and propane, ensuring flexibility for different setups. The boiler must be connected to a gas supply line that meets local regulations and safety standards. For natural gas, the supply pressure should range between 20 mbar and 25 mbar, while propane systems require a pressure of 37 mbar. Proper gas flow rate and inlet pressure are critical to avoid operational issues. The installation must comply with standards such as BS 5440-1 for propane-fired boilers. Incorrect gas type or pressure can lead to faults or combustion noise. Always ensure the gas supply is compatible with the boiler’s specifications. This ensures safe and efficient operation, preventing potential shutdowns or damage.

Ventilation and Air Supply

Proper ventilation is crucial for the Vaillant EcoTEC Pro 28 to ensure safe and efficient operation. As a condensing boiler, it requires adequate airflow to expel flue gases and maintain optimal performance. The boiler is designed as a room-sealed appliance, meaning it does not require an air vent in the room where it is installed. However, the flue system must be correctly installed to prevent flue gases from re-entering the building or causing damage. The flue termination must be positioned at least 600 mm away from any adjacent windows, doors, or air intakes to avoid gas re-circulation. Additionally, the flue system should be shielded to prevent ignition or damage to nearby materials. Always follow local regulations and the manufacturer’s guidelines for flue installation to ensure compliance and safety. Proper ventilation ensures the boiler operates efficiently while maintaining a safe environment.

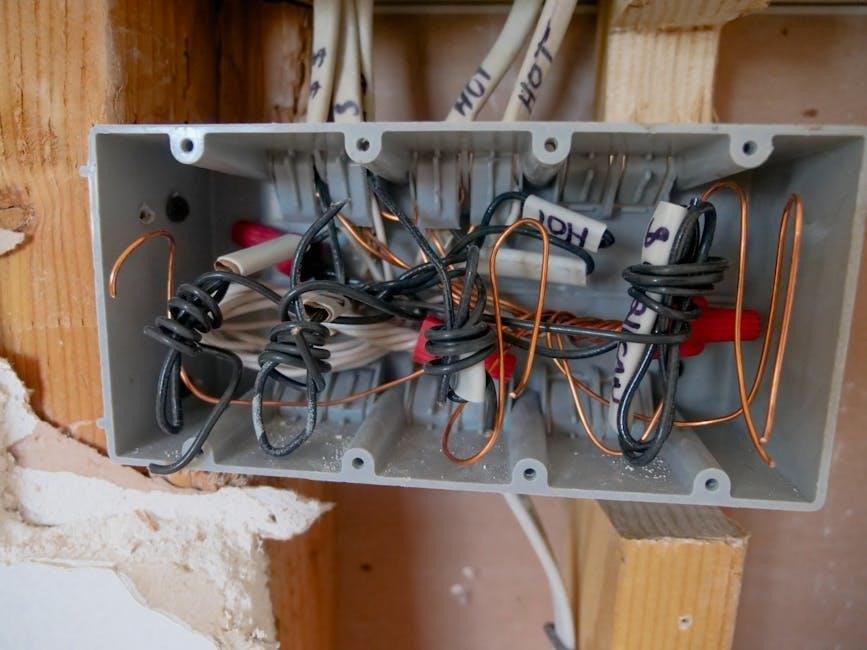

Electrical Connections

The Vaillant EcoTEC Pro 28 requires a 230V AC electrical supply to operate. The boiler is designed with a plug-and-play system for easy installation, but all electrical work must be carried out by a qualified electrician. The controller should be connected according to the wiring diagram provided in the manual. Ensure the mains voltage is within the specified range (190-253V AC) to avoid malfunctions. The boiler features a removable control panel for easy access during servicing. When connecting the controller, route the mains cable through the designated cable duct on the boiler’s base. Use the provided strain reliefs to secure the wiring and avoid damage. Always refer to the wiring diagram in the manual for specific connections. The boiler is compatible with external controls, such as programmable room thermostats, to enhance functionality. Proper electrical connections are critical for safe and efficient operation. Follow all safety guidelines and manufacturer instructions to ensure compliance and reliability.

Installation Steps

The Vaillant EcoTEC Pro 28 installation involves wall-mounting the boiler, connecting water and gas supplies, installing the flue, and setting up electrical connections. Follow the manual for precise steps.

Wall-Mounting the Boiler

Wall-mounting the Vaillant EcoTEC Pro 28 is a straightforward process that ensures optimal performance and easy maintenance. Begin by unpacking the boiler and carefully removing it from the packaging. Ensure the installation site meets the required clearances, with at least 500 mm of space in front of the boiler for servicing access. The boiler comes pre-assembled with a wall bracket, which simplifies the mounting process; Locate the wall bracket on a stable, vertical surface, ensuring it is level and securely fastened. Hang the boiler on the bracket by aligning the mounting hooks on the back of the unit with the corresponding slots on the bracket. Gently lower the boiler into place and secure it by tightening the provided screws. Ensure the boiler is stable and evenly balanced to prevent any tilting. Once mounted, double-check that all connections (water, gas, and electrical) are accessible for future maintenance. Proper wall-mounting is crucial for the boiler’s efficiency and safety.

Connecting Water and Gas Supplies

Connecting the water and gas supplies for the Vaillant EcoTEC Pro 28 is a critical step in its installation. Begin by ensuring the boiler is properly wall-mounted and the necessary isolation valves are installed. Connect the cold water supply to the inlet on the bottom of the boiler, and the hot water outlet to the appropriate heating system. The central heating flow and return connections should be made according to the system’s requirements. For the gas supply, ensure the correct gas type (natural gas or propane) is used, and the gas pipe is sized appropriately to meet the boiler’s demand. The gas connection should be tightly sealed to prevent leaks, and a gas test must be performed to ensure system integrity. Finally, connect the discharge pipe from the expansion relief valve to a suitable drainage point. Always follow local regulations and safety guidelines during these connections. Proper installation ensures safe and efficient operation of the boiler.

Flue Installation and Termination

Proper flue installation and termination are essential for the safe and efficient operation of the Vaillant EcoTEC Pro 28. The flue system must be installed according to local building regulations and the manufacturer’s guidelines to ensure correct ventilation of combustion gases. Use a flue pipe with a diameter of 60/100 mm or 80/125 mm, depending on the boiler’s output and installation requirements. The flue should be terminated at least 600 mm above the roof or 300 mm above any opening within 3 meters horizontally to prevent gas re-entry. For balanced flue systems, install a concentric flue kit to ensure proper air intake and flue gas expulsion. Avoid flue termination near flammable materials or in areas where gases could accumulate. Ensure all connections are sealed tightly to prevent leaks. Refer to the installation manual for specific termination kits and accessories, such as bends or extension pipes, to complete the flue system correctly. Proper flue installation ensures compliance with safety standards and optimal boiler performance.

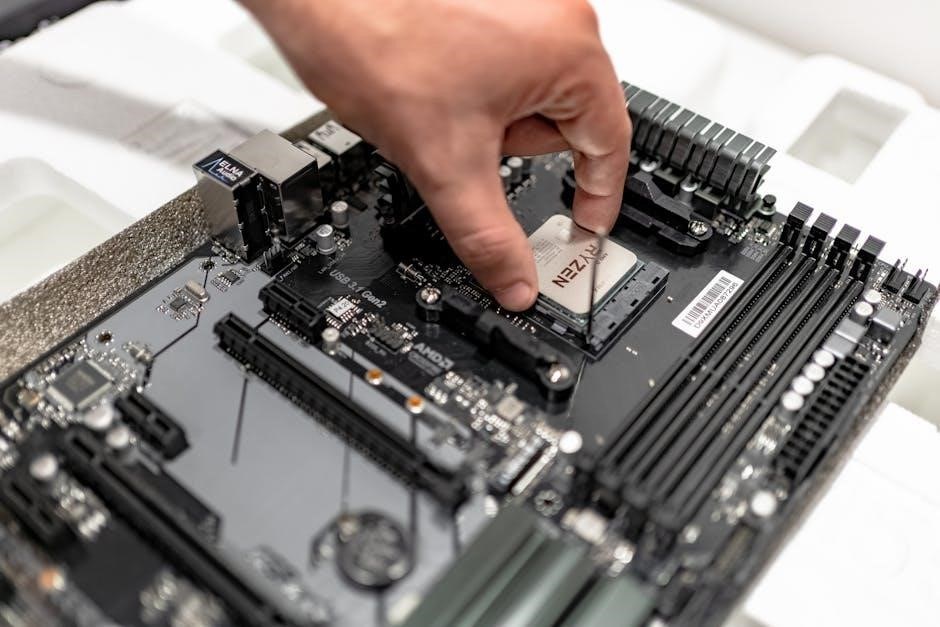

Electrical Installation and Controller Setup

The electrical installation and controller setup for the Vaillant EcoTEC Pro 28 require careful attention to ensure safe and efficient operation. Begin by connecting the mains supply to the boiler, ensuring the voltage matches the rated 230 V AC. Route the mains cable through the designated duct on the boiler’s base to maintain a neat and secure installation. Next, install the controller, such as a room thermostat or programmable controller, following the manufacturer’s instructions. Connect the controller to the boiler’s electronic system, using the provided strain reliefs to protect the wires. Ensure all connections are secure and comply with local electrical standards. The boiler’s electronics box is designed for compatibility with Vaillant’s eBUS system, allowing for plug-and-play functionality with optional accessories. After completing the wiring, test the system to ensure all components communicate correctly. Proper electrical setup is crucial for optimal performance, safety, and energy efficiency. Always refer to the installation manual for specific wiring diagrams and guidelines.

Maintenance and Servicing

Regular maintenance ensures optimal performance, safety, and longevity of the Vaillant EcoTEC Pro 28. Annual servicing by a qualified technician is essential to check gas flow, flue integrity, and electrical connections.

Regular Maintenance Schedule

Regular maintenance is crucial to ensure the Vaillant EcoTEC Pro 28 operates efficiently and safely. Annual servicing by a qualified technician is required to inspect the boiler’s internal components, such as the heat exchanger, burner, and flue system. This ensures proper gas flow, combustion, and venting of exhaust gases. Additionally, the technician will check the electrical connections and controls for any faults or wear.

Homeowners should also perform routine checks, such as monitoring the boiler’s pressure gauge monthly and ensuring it remains within the recommended range (typically 1-2 bar). The area around the boiler should be kept clean and well-ventilated to prevent dust buildup and maintain airflow. Users are advised to inspect visible pipes and connections for leaks or damage and address them promptly.

It is important to follow the manufacturer’s guidelines and use genuine Vaillant replacement parts to maintain warranty validity. Regular servicing not only prolongs the boiler’s lifespan but also ensures optimal energy efficiency and performance. Always consult a qualified technician for any maintenance or repairs to avoid safety risks and potential damage to the system.

Tips for Optimal Performance

To maximize the efficiency and performance of the Vaillant EcoTEC Pro 28, follow these essential tips. Always ensure the boiler is installed and maintained according to the manufacturer’s guidelines. Regularly check the gas flow rate to confirm it matches the boiler’s specifications, as incorrect flow rates can reduce efficiency and cause operational issues.

Ensure proper ventilation in the room where the boiler is installed, as inadequate airflow can lead to incomplete combustion and reduced performance. Utilize the Vaillant eBUS system for smart control, as it allows for precise temperature regulation and energy-saving operation. Additionally, consider upgrading to a programmable room thermostat for better control over heating schedules.

Keep the boiler’s surroundings clean and free from dust or debris, which can interfere with airflow and component function. If using propane, ensure the boiler is specifically configured for propane operation to avoid compatibility issues. Finally, always use genuine Vaillant parts for repairs or replacements to maintain performance and warranty validity.